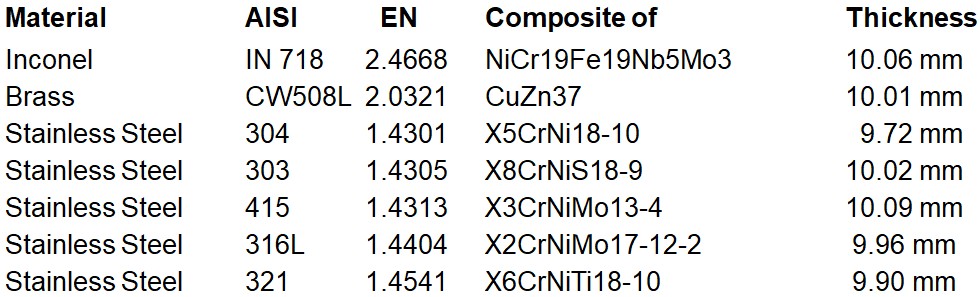

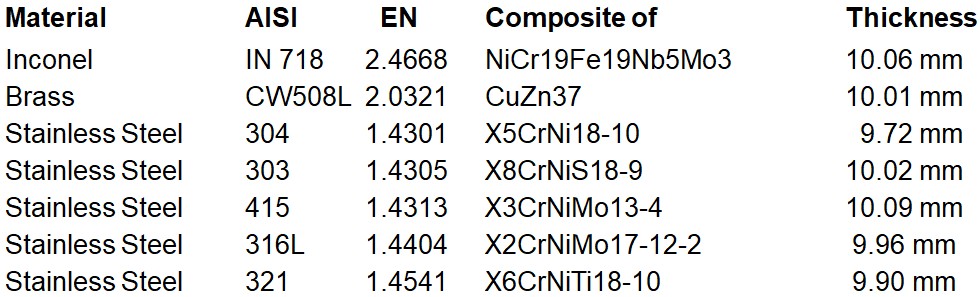

The following materials were in the test:

Additional to the Inconel plate – which is required in E2597 - we also took a plate of brass as reference because brass is known to have nearly no internal structures and should be the reference.

Within the test we took images of each material with 1s, 4s, 16s, and 64s exposure time. For the presentation of the results here the 64s values (longest time) are used.

Of each material we took two images at identical positions; the subtraction of both images shows only the X-ray noise as all structures are removed by the subtraction.

Then we moved the plate by about 10mm in both directions (0.7“diagonal) and took a third image of each material with the same parameters as before. The subtraction of third images from the first image shows the fixed pattern noise (material structure) and the X-ray noise. As we have the X-ray noise from the previous image series we can subtract the X-ray noise (variances) from the total noise and get the fixed pattern noise.

The first picture shows the signal level of the 10mm plates with 200kV.

The highest absorption comes with brass, Inconel is close. Most of the steels have nearly double the signal level, only SS316L (SS1.4404) has a higher absorption.

The total SNR (SNR of X-Ray and Material) shows the achievable performance level which you could measure in practice.

From the difference images we get the SNR of X-Ray which is proportional to the square root of the signal. This is conforming to the theory.

Now we can calculate the fixed pattern noise of the material which I call the SNR of the material.

Here we see very big differences for the different steels. Also the Inconel performs quite good – the Inconel for the test got heat treatment to remove most of the structures, which was quite successful. But nevertheless the steel SS316L (SS 1.4404) performs 60% better …

Finally also the visual impression is important to accept a new material:

Brass is very homogeneous and show only little structures; Steel 316L (SS 1.4404) show moderate structures with wide spread; this heat treated Inconel performs quite well, but the structures in medium size are well visible and should be avoided in an IQI.

In the relationship to the X-Ray noise we see a clear winner: Brass.

As the workgroup in ASTM decided not to use brass or cooper, the recommendation for Steel 316L is obvious:

- it shows fewer structures than Inconel

- it provides a better SNR than Inconel or other steels

- it does not need a special treatment as Inconel does

- it is more easy to machine

- it is cheaper and more easy available on the international market.

Finally it has the highest absorption of all steel alloys in the test and is therefore closest to the Inconel.